��ҵ��� �۽���ϿƼ�����˾��һ�Ҵ��¸��ֽ��������Ʒۼ����з�����ĩ��ƷӦ��Ϊ�����Ĺ��Ҹ��¼�����ҵ����˾������������ϵͳ�з�ʼ��1996�꣬��ĩ����ƽ̨ʼ��2000�ꡣ30,000�������������ĩ������ʵ���ǻ۽�ȡ֮�����IJƸ�ԴȪ��ʹ�۽��Ϊ�Ƚ��p�걸��������ĩ�������豸��������ҵ���ġ����ڽ�����ĩ��Ʒ���۽�˾רע���ϵ�Ӧ�����Խ����������ƣ������ĩ���ϸ�������Ʒ�ʡ�������ܶ��ս���ϡ������ʵ�в��ϡ��ߴ��ȴ����ϡ����氲���������ϡ����Ӳ�����ơ���ĩ������������Ӧ�ã������ֿ�ѧ���������������ںϡ��۽������ĩ���Ϲ㷺Ӧ���ڷ�ĩұ��pע����ͩp���p3D��ӡ�����Ӳ��ϵȲ�ҵ���� Huijin Atomizing is a professional national Hi-Tech company that devotes to atomizing technologies development and powder material application. Our systematic development of atomizing technology(CCGA) was since 1996 and powder production since 2000. More than 30000 tones metal powder have been sold in the past years. Accumulated from extensive R&D activities and the experiences in metal powder production, these abundant resources are promoting Huijin to be a reliable provider of the advanced metal powder materials. Huijin��s R&D focused on the features of material application. Perfect characteristics were deposited in the powder products, such as high density sintering materials, lower impurity inductance materials, high purified catalytic materials, and surface stable low oxygen materials�� Huijin integrated comprehensive sciences on our powder products, from material designing, manufacturing, and application�� Various kind of metal powders are available. These tailor-made products cover from Fe/Ni/Co/Cu base alloys to tin base alloys. They are applied in a wide range of industries, such as powder metallurgy, MIM, catalytic material, 3D printing, and electronic materials.

��Ʒ����

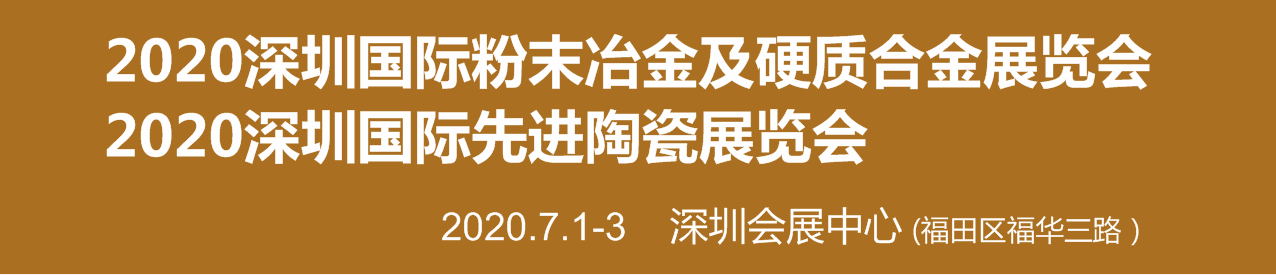

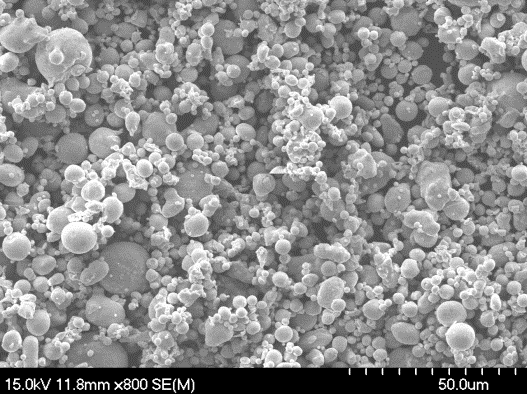

ˮ���������η�ĩ ��water atomized MIM powders�� 1.�����������Ӧ�õ���ϸ�����ʷ�ĩ4.�������ֲڶ�С, MIM������ʸк�����ַ�ĩ��316L��304L��17-4PH��̼�ַ�ĩ�� HK30��420��440��SKD11��1.The finest industrialized powders applied in MIM industry3.Easily to be sintered with very high density and low deformation4.Shiny appearance with lower surface roughness

������ĩPANACEA/17-4N���� ��Nitrided Powder Materials�� �������� 1.����PANACEA ����,1260���ս�ʱ��ȫ�����廯�IJ��ϣ��ܶ�7.72 2.����17-4 N ,��, �������

General characteristics 1.High surface activity of PANACEA material,Completely austenitized structure sintered at 1260�� with a density of 7.72g/cm3. 2.Nitrided 17-4 N is Non-magnetic and suitable for high gloss surface polishing.

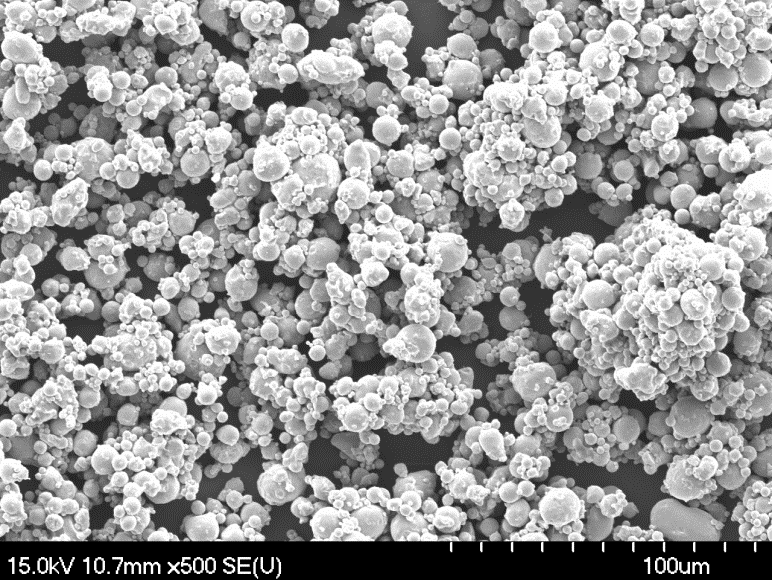

����316L-G ��High Gloss Surface 316L-G�� �۽�����ĩ���Ͼ������ص���ƣ����ص�Ϊ�� 1.���ܶȣ��ս��ܶȷ�Χ��7.93~7.97g/cm3 2.�Ϳ�϶�ʣ���϶�ʷ�Χ��0.2~0.5% 3.���������ٶ���С 4.����߹�������� 5.�����Ͳ��϶��ս�¯����������

Many unique technologies were applied in the high gloss surface 316L-G powder material: 1.Able to get high sintering density, and typical range within 7.93~7.97g/cm3 2.Low sintering void ratio, typical range at 0.2~0.5% 3.Decreasing the large concentrated sintering voids both in size and numbers 4.Shiny and smooth sintering surface design 5.Low manganese content material design is benefit for sintering furnace lifetime

��ϵ��ʽ ���ݻ۽���ϿƼ�����˾

�㶫��չչ������˾ ������չ��ҵЭ��(UFI)�й�����Ա���㶫��չ��չ��ҵЭ�ḱ�᳤��λ���й�ʮ��Ʒ����չ�̣� �绰��020-29193588��29193589

|